PRODUCTS

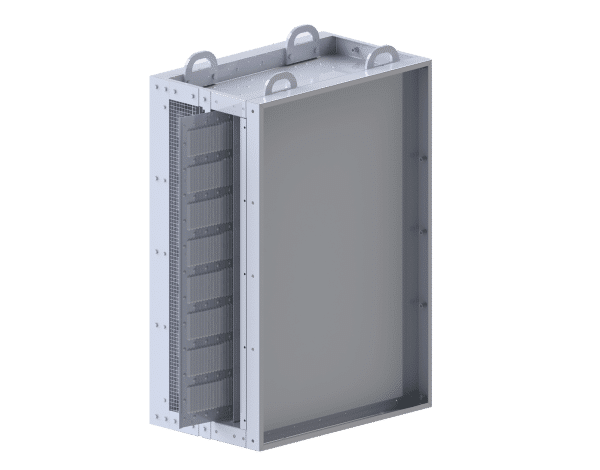

FC-BRV-02-E(M) Rapid Blast Damper

FC-BRV-02-E(M) rapid blast dampers are specifically developed for those applications where high air flow rate and blast protection are required. It could stand the overpressure up to 200KPa reflected with long duration and shut off in milliseconds. It could also stand multiple blast impacts and maintain full functions after blasts.

FC-BRV-02-E(M) rapid blast dampers provide manual-reset function. Once the blast dampers are closed by the blast waves their blades will be locked at closing position until they are reset manually. This manual-reset function provides extra safety margin for applications.

Additional information

| Stand strong blast impulse | Able to stand multiple blast impacts and maintain all functions after blasts. |

|---|---|

| Unparralled rapid response speed | Completely closed within 8ms under 200KPa peak pressure reflected and this assures the safety by minimizing the passing through impulse. |

| High ventilation volume | High air flow based on normal open position. A 500*500 blast damper could provide exhaust flow rate up to 3800 m3/h at pressure differential 100Pa. |

| Manual-reset | Maintain at closing position through self-lock mechanism to provide extra safety. |

| High corrosion resistant performance | Made of chemical-resistant material and fit all corrosive conditions. |

| ATEX certified | Safely work in explosive atmospheres. |

| Designed peak pressure | 200KPa Reflected |

| Designed blast duration | 20ms |

| Closing time | <8ms (200KPa reflected) |

| Blast impulse block rate | >98.5% (200KPa reflected) |

| Operating temperature | -30ºC to 285ºC |

| ATEX Certification | Certification No. TÜV 15 ATEX 7741 X Ⅱ2 G c ⅡC T6…T2 Ⅱ2 D c ⅢC T70℃…T285℃ |

| A. Material of damper | 1-Stainless Steel 316L, 2-Stainless Steel 304L, 3-Hot galvanized steel, 4-Epoxy coated steel (Non-ATEX) |

| B. Mounting Type | IW–In the wall, OW–On wall surface, D–Duct connected |

| C. Width (mm) | 0300, 0500, 0700, 1000, 1200, 1500, … |

| E. Height | 0300, 0500, 0700, 1000, 1200, 1500, … |

| Certificates | Product is type tested at AMCA(US), TUV(Germany). Test reports are available upon request. |

| Applications | OGP, Chemical, Chemical, Power, Marine, Mining, Civil defense |